Preventive Maintenance

Minimizing downtime is essential to keeping profits up and costs down. Let Sheridan Electric help you be proactive about electrical preventive maintenance of your distribution & control systems. We can help maximize equipment lifespans and minimize costly production downtime.

Infrared Imaging Scans

Electrical Infrared thermograph imaging inspections are done proactively to spot problems before they happen, and do not require any facility downtime.

High & Low Voltage MAINTENANCE

Testing and maintenance of your high voltage transformers is critical to ensuring their long-term health and reliability.

EQUIPMENT Maintenance

We can design a customer preventive maintenance program designed around your specific equipment at either the single-plant or corporate level.

spot problems before they happen

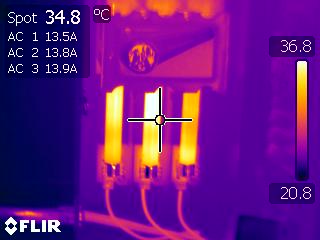

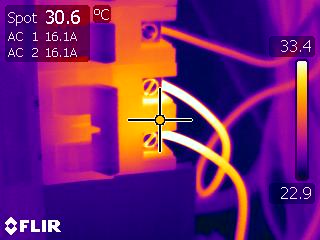

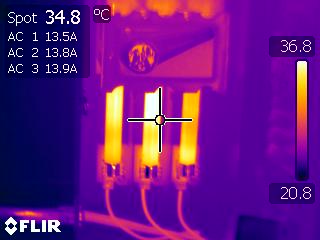

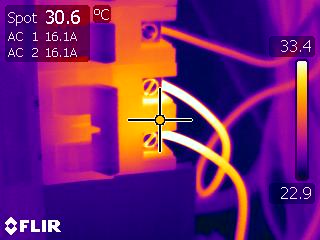

Infrared scanning spots problems before they happen, by checking equipment for temperature ranges that exceed manufacturer recommendations. This kind of smart electrical preventive maintenance can be done in a prioritized and planned way, reducing unwanted downtime. Scanning reports are also frequently requested by insurance providers.

- We do it while your plant is running – no production downtime or shutdown is needed. (We recommend doing the scan during a peak production period such as summertime when the AC units are running.)

- We can provide an electrician to open all the equipment for scanning. All our electricians and technicians have the proper Arc Flash training and safety gear (PPE) to conduct the scan safely.

- Everything is confidential. We do not release the data to anyone unless you request it.

- We can also scan your production equipment control panels, and spot issues with critical electrical parts like contactors, transformers, and terminals – preventing an inexpensive part from bringing down your production.

- We scan all critical power distribution – including your main incoming service, capacitor banks, transformers, MCC cabinets, circuit panels, and more.

spot problems before they happen

Infrared scanning spots problems before they happen, by checking equipment for temperature ranges that exceed manufacturer recommendations. This kind of smart electrical preventive maintenance can be done in a prioritized and planned way, reducing unwanted downtime. Scanning reports are also frequently requested by insurance providers.

- We do it while your plant is running – no production downtime or shutdown is needed. (We recommend doing the scan during a peak production period such as summertime when the AC units are running.)

- We can provide an electrician to open all the equipment for scanning. All our electricians and technicians have the proper Arc Flash training and safety gear (PPE) to conduct the scan safely.

- Everything is confidential. We do not release the data to anyone unless you request it.

- We can also scan your production equipment control panels, and spot issues with critical electrical parts like contactors, transformers, and terminals – preventing an inexpensive part from bringing down your production.

- We scan all critical power distribution – including your main incoming service, capacitor banks, transformers, MCC cabinets, circuit panels, and more.

High & Low Voltage Maintenance

Electrical Systems Maintenance

Every facility is different and has unique needs. We work with you to design an electrical preventive maintenance program including:

- High Voltage Transformer Testing: We preform oil and gas tests on high voltage transformers – including standard ASTM tests, DGA, Water and power factor.

- High Voltage Transformer Maintenance: We provide annual maintenance programs for your substation – including inspecting and cleaning, confirming torque, operation of all devices, TTR testing, resistance testing, and more.

- Local Utility: When repairs or annual maintenance is required, we handle coordination with the local utility for shut-off of your substation.

- Low resistance testing prevents long-term damage and minimizes energy waste, and is usually applied to circuit breakers. This testing will indicate any restriction in current flow that might hinder a machine from generating its full power. Periodic testing can assess the internal condition of equipment, and through trending can point to potential future failure.

- Wire Insulation (Megger) testing & reporting spots wire deterioration in new or existing systems. This is usually done as part of a larger preventive maintenance package, but can be done as needed (such as testing of underground wiring).

- General Maintenance: Insulation testing of primary low voltage cabling, cleaning, re-torquing checks, mechanical operation of switches, visual checks and more.

Electrical Systems PREVENTIVE Maintenance

Every facility is different and has unique needs. We work with you to design an electrical preventive maintenance program including:

- High Voltage Transformer Testing: We preform oil and gas tests on high voltage transformers – including standard ASTM tests, DGA, Water and power factor.

- High Voltage Transformer Maintenance: We provide annual maintenance programs for your substation – including inspecting and cleaning, confirming torque, operation of all devices, TTR testing, resistance testing, and more.

- Local Utility: When repairs or annual maintenance is required, we handle coordination with the local utility for shut-off of your substation.

- Low resistance testing prevents long-term damage and minimizes energy waste, and is usually applied to circuit breakers. This testing will indicate any restriction in current flow that might hinder a machine from generating its full power. Periodic testing can assess the internal condition of equipment, and through trending can point to potential future failure.

- Wire Insulation (Megger) testing & reporting spots wire deterioration in new or existing systems. This is usually done as part of a larger preventive maintenance package, but can be done as needed (such as testing of underground wiring).

- General Maintenance: Insulation testing of primary low voltage cabling, cleaning, re-torquing checks, mechanical operation of switches, visual checks and more.

EQUIPMENT PREVENTIVE MAINTENANCE Programs

Equipment PREVENTIVE MAINTENANCE

Preventive maintenance of production machinery can greatly increase the long-term reliability and effectiveness of the machinery. We work on your scheduled downtime days (including evenings and weekends) so you never have to worry about lost production. Some of our services include.

- Low Voltage Signal Monitoring

- Harmonics and Power Logging Studies

- PLC, HMI, and other Control System Audits

- Cleaning

- Infrared Scans

- Profibus Predictive Scanning & Diagnosis

- Temperature and Humidity Logging

Equipment PREVENTIVE MAINTENANCE

Electrical preventive maintenance of production machinery can greatly increase the long-term reliability and effectiveness of the machinery. We work on your scheduled downtime days (including evenings and weekends) so you never have to worry about lost production. Some of our services include:

- Low Voltage Signal Monitoring: Intermittent and nuisance issues can be difficult to pinpoint. Our testing instruments can log multiple signals at one time, to help isolate the possible source of an issue.

- Harmonics and Power Logging Studies: Noise issues can be hard to diagnose, and having the proper instruments is critical to isolating the issue.

- PLC, HMI, and other Control System Audits: Including backing up of programs and electrical documentation (e.g. schematics).

- Cleaning: Control cabinet cleaning and tightening of connections.

- Infrared Scans: Reporting & Analysis of Control Cabinets and LV Equipment. Our infrared cameras can pick up temperature issues in control cabinets, such as overheating transformers, circuit breakers, and even loose connections.

- Profibus Predictive Scanning & Diagnosis: We have the testing instruments to monitor and report on the health of a network and pinpoint connection deterioration. This allows manufacturers to plan production downtime, taking proactive steps to stop problems before they happen. We can also diagnose in emergency situations.

- Temperature and Humidity Logging: Humidity can lead to condensation which can damage electrical instruments, and excessive heat can cause components to fail. We can log data in any electrical cabinet and help stop issues before they happen.

health & safety

Safety is our number one priority. We are committed to ensuring the health & safety of every employee and to performing all operations in a safe and effective manner. The safety of every employee is an integral component of our business practice. Accident prevention and quality of working life are essential parts of our business operations.

Management, supervisors and all employees are responsible for contributing to the upkeep and constant betterment of our health & safety program. We believe that by working together, maintaining open lines of communication, and giving the most careful attention to health & safety, we will meet our shared objective of a healthy and safe working environment.

Sheridan Electric is accredited by, and working with, multiple contractor safety compliance companies.